GENERAL INFORMATION HOW DOES A SUCTION CUP WORK?

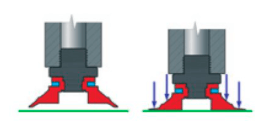

A suction cup adheres to a surface when the surrounding pressure (atmospheric pressure) is higher than the pressure between the suction cup and the surface of the object. To create the low pressure in the suction cup it is connected to a vacuum source. The lower the pressure, the higher the vacuum in the suction cup – resulting in increased lifting force.

SAVINGS IN ENERGY AND SYSTEM COSTS

SAVINGS IN ENERGY AND SYSTEM COSTS

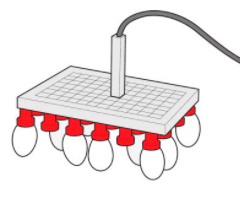

Leakage occurs in a system when one or more suction cups do not contact the object being handled. This may happen in applications where the number, the position or the size of the objects to be lifted vary. Usually a large vacuum pump is used to cope with the air leakage and to maintain the vacuum level. The result is an inefficient system in terms of energy and capital costs. A better solution is to use fittings with valves. The valves stop or reduce the leakage so that a smaller, more appropriate vacuum pump can be used to decrease installation and operation costs.

Safety Factors

Safety Factors

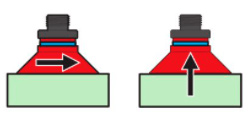

The lifting force can be perpendicular or paralel to the surface to be handled. The values are based on sample data for a dry steel plate. When sizing a suction cup, we recommend to always multiply the weight of the object to be handled by a minimum factor of 2 for increased safety.